Sherwin-Williams' WeatherXL™ Coil Coating System

Superior Durability

WeatherXL™ is a better and more durable version of Sherwin-Williams' silicone-modified polyester (SMP) coating resin system that is designed to go where it will be abused.

It was created to withstand almost anything and features superior weatherability, tremendous color and gloss retention, resistance to chalking, fading and scratching, and extreme resistance to abrasion, chipping and marring.

Multitude of Applications

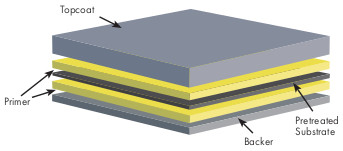

WeatherXL™ may be applied to a number of pretreated substrates such as aluminum, Galvalume®, and hot-dip galvanized (HDG) steel.

It is ideal for a variety of residential, commercial, industrial, and agricultural applications such as: metal building components, metal roofing, metal wall panels, pre-engineered metal building systems, siding, gutters, downspouts, and much more.

A Choice of Distinctive Colors

WeatherXL™ coatings are available in a wide palette of

colors and feature outstanding consistency and exceptional gloss retention.

These cool coating formulations help lower the overall temperature of the structures, enabling savings on energy costs, all while providing exceptional durability.

Polar White

Light Stone

Saddle Tan

Ash Gray

Old Town Gray

Hawaiian Blue

Rustic Red

Crimson Red

Berry

Charcoal

Cocoa Brown

Burnished Slate

Gallery Blue

Evergreen

Ivy Green

Black

Commitment to Quality

WeatherXL™ coatings are trusted and field-proven through rigorous testing, providing key benefits to our customers.

| SMP COIL COATING SYSTEM | |||||

|---|---|---|---|---|---|

| Number of Coats | Dry Film Thickness (DFT) | Total Topside DFT: | |||

| Primer | Topcoat | Backer | |||

| 2-Coat | 0.2 - 0.3 mils | 0.7-0.8 mils | 0.9-1.1 mils | 0.2-0.3 mils | |

| WEATHERXL™ AND WEATHERXL CRINKLE FINISH PERFORMANCE TESTING | ||

|---|---|---|

| Industry Specifications Compliance | AAMA 2604-17A Requirements | Voluntary Specification, Performance Requirements and Test Procedures for HighPerforming Organic Coatings on Architectural Aluminum Extrusions and Panels |

| Substrates | Pretreated Galvalume, Hot-Dipped Galvinized (HDG) steel and aluminium | |

| PHYSICAL TESTING | ASTM1 TEST METHOD | AAMA2 2604-17A REQUIRED TEST RESULT |

|---|---|---|

| Falling Sand Abrasion | ASTM D 968 | 35 ± 10 liters |

| Film Adhesion | ASTM D 3359 | No removal of film under tape in the cross-hatched area. (Dry, Wet, Boiling Water) |

| Surface Burning Characteristics | ASTM E 84 | Flame Spread Index: Class A. Smoke Developed Index: Class A. |

| Graffiti Resistance | ASTM D 6578/D 6578M | Meets and exceeds |

| Humidity Resistance | ASTM D 2247: 100% RH at 100° F for 2,000 hours | Galvalume or HDG: No field blisters Aluminum: No field blisters |

| Impact Resistance (direct) | ASTM D 2794 | Galvalme or HDG: 3x metal thickness inch-pound, no loss of adhesion |

| Pencil Hardness | ASTM D 3363 | HB to 2H. |

| Salt Spray | ASTM B 117: 1,000 Hours 3,000 Hours | Galvalume or HDG: Creep from scribe ≤ 1/8" (3mm), none or few #8 blisters. Aluminum: Creep from scribe ≤ 1/8" (3mm), few#8 blisters. |

| Specular Gloss 60° | ASTM D 523 | WeatherXL: 20-80 WeatherXL Crinkle Finish: <5 @ 60 degrees |

| T-Bends | ASTM D 4145³ | 2T-4T, no loss of adhesion. |

| SOUTH FLORIDA EXPOSURE TESTING 45 degree southern exposure for panel racking | ||

|---|---|---|

| Color | ASTM D 2244 | No more than 5∆ E Hunter units at 90° vertical angle and 6∆ E non-vertical at 20 years. |

| Chalk | ASTM D 4214 | Rating no less than 8 at 90° angle and 7 at non-vertical angle at 20 years. |

| Film Integrity | ASTM G 7 | 25 years, no blisters, peeling or cracking |

1 American Architectural Manufacturers Association.

2 American Society for Testing and Materials.

3 WeatherXL is not designed to bridge cracks in the substrate. WeatherXL coatings will generally meet the requirements for most post-painted fabrication processes. However, variations in metal quality, thickness or cleaning/pretreatment applications can lead to diminished flexibility.

For details and health, safety and handling information, Material Safety Data Sheets (MSDS) are available at coil.sherwin.com. WeatherXL™ is a registered trademark of Sherwin-Williams. Galvalume® is a registered trademark of BIEC International, Inc.

Sherwin-Williams makes no warranties, expressed or implied, and disclaimers all implied warranties including warranties of merchantability or fitness for a particular use. Sherwin-Williams will not be liable for any special, incidental or consequential damages. © 2018 Sherwin-Williams. All Rights Reserved.